Industrial gas storage tank

Keywords:

Keywords:

Industrial gas storage tank

Category:

Product Description

Storage tanks are specialized equipment used for storing industrial gases (liquid oxygen, liquid nitrogen, liquid argon). The tank body insulation structure adopts three forms: high-vacuum multilayer insulation, vacuum powder insulation, and vacuum composite insulation. The storage tank consists of an inner container and an outer shell. The inner container uses austenitic stainless steel S30408 with excellent low-temperature performance as the main material, and the outer shell uses Q345R pressure vessel steel plate as the main material. The vacuum layer between the inner and outer containers is filled with dried expanded perlite (pearl sand), or insulation composite paper is wrapped around the inner container and vacuum qualified. The storage tank is equipped with an air-cooled booster to self-pressurize the tank, meeting the needs of tank unloading and gas use. Through reasonable structural design and mature manufacturing processes, the insulation performance and service life of the storage tank are reliably guaranteed. The design, manufacturing, inspection, and acceptance of this storage tank fully meet the safety technical requirements of the "Safety Technical Supervision Regulations for Stationary Pressure Vessels" and relevant national standards, providing strong guarantees for the safe use of the equipment. The storage tank features a reasonable structure, good insulation performance, safety and reliability, convenient operation, and easy maintenance, making it ideal specialized equipment for storing industrial gases.

Product Description:

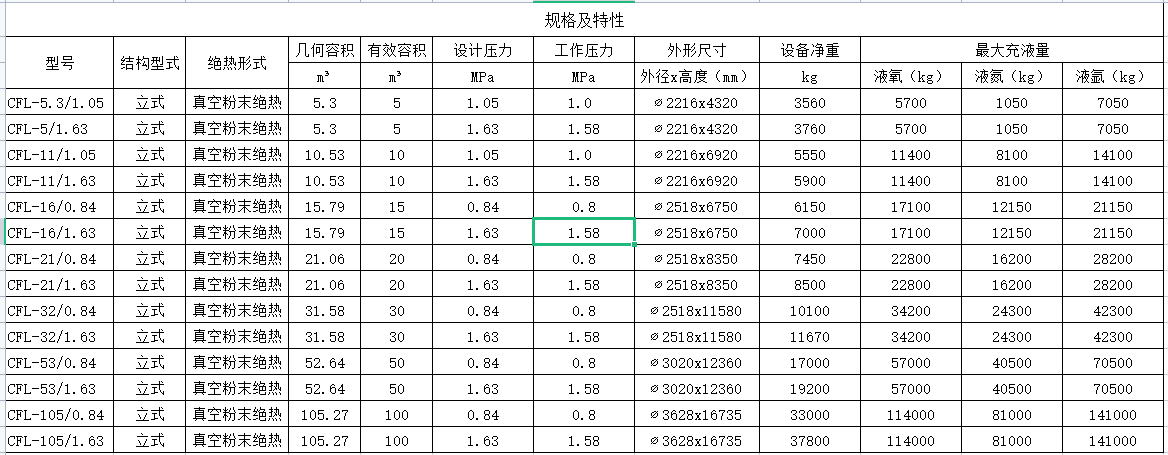

This series of industrial gas cryogenic liquid storage tanks comes in various specifications, with working pressures of 0.8 MPa and 1.6 MPa as standard tank series. The inner tank uses strain hardening technology. The unique process ensures stable insulation performance and vacuum degree. The structure is compact, and operation and maintenance are convenient. Special pressure, volume specifications, and structural forms can be customized according to customer requirements.

Technical Parameters

Related Products

Welcome your message inquiry